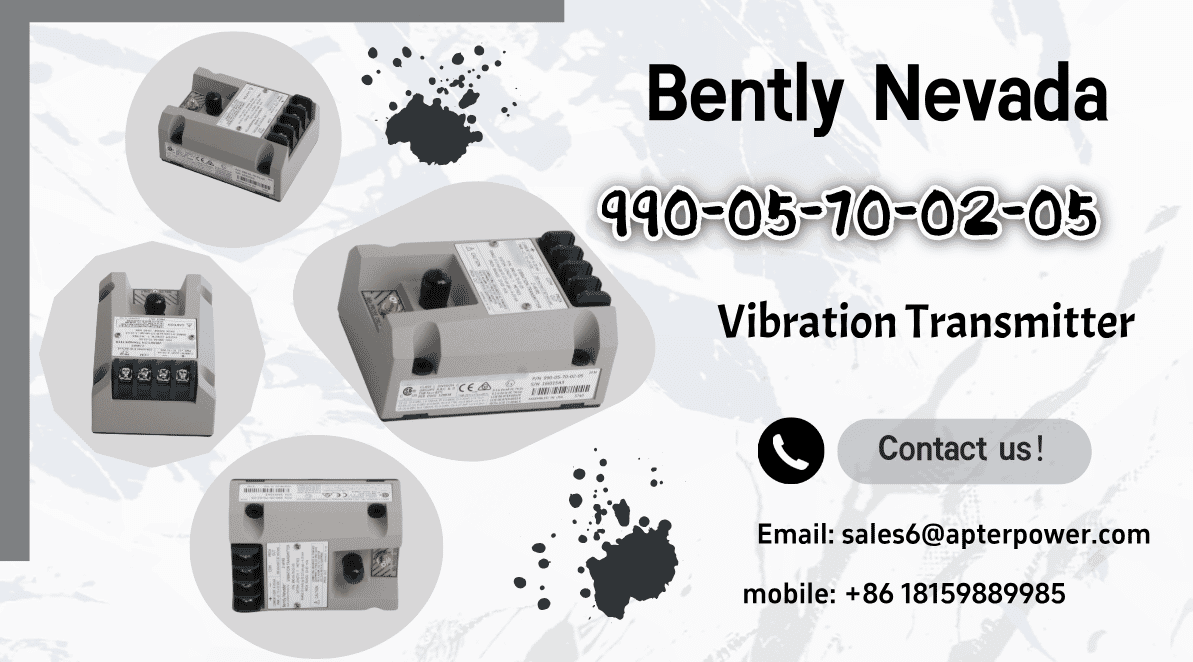

The Bently Nevada 990-05-70-02-05 is a high-performance vibration transmitter designed for precise machinery condition monitoring in industrial applications. As part of the renowned Bently Nevada product line by Baker Hughes, this device plays a crucial role in detecting and analyzing vibration levels in rotating equipment such as turbines, compressors, pumps, and motors.With industries increasingly prioritizing predictive maintenance, the 990-05-70-02-05 transmitter helps prevent unexpected failures by providing real-time vibration data. Its robust design ensures reliable operation in harsh environments, making it a trusted choice for oil & gas, power generation, and manufacturing sectors.

Unmatched Reliability for Mission-Critical Operations

The Bently Nevada 990-05-70-02-05 stands as the gold standard in vibration monitoring, trusted by maintenance teams worldwide to safeguard their most valuable rotating assets. Engineered for non-stop performance, this transmitter delivers precise vibration data that keeps turbines spinning, compressors running, and production lines moving. Its military-grade construction shrugs off the harshest plant conditions - whether it's the scorching heat of a desert oilfield or the corrosive atmosphere of a coastal refinery.

What sets this transmitter apart is its ability to maintain measurement integrity where others fail. While standard sensors might drift or falter under continuous vibration loads, the 990-05-70-02-05 locks onto true vibration signatures with unshakable accuracy. It's this reliability that makes it the first choice for engineers who can't afford guesswork when monitoring million-dollar equipment.

Smarter Monitoring Through Advanced Engineering

At the heart of this transmitter lies sophisticated vibration analysis technology that speaks the language of modern control systems. The instant conversion of mechanical vibrations to crisp 4-20mA signals means your SCADA system gets clean, actionable data - not noise. This isn't just monitoring; it's diagnostic-grade intelligence flowing directly to your control room.

The device's wideband sensing acts like a mechanical stethoscope, picking up everything from the faintest bearing whisper to the loud shout of impending gear failure. Whether it's a 10,000 RPM turbine or a slow-turning slurry pump, the transmitter captures the full vibration story. And with its battle-tested enclosure, it keeps telling that story year after year, through temperature swings, moisture attacks, and constant vibration punishment.

Transforming Maintenance from Cost Center to Profit Driver

This is where the 990-05-70-02-05 pays for itself repeatedly. By catching problems in their infancy, it turns potential disaster into scheduled maintenance. Imagine detecting a bearing defect three months before failure - that's three months of continued production instead of three weeks of emergency downtime.

If you want to know details,please contact me without hesitate.